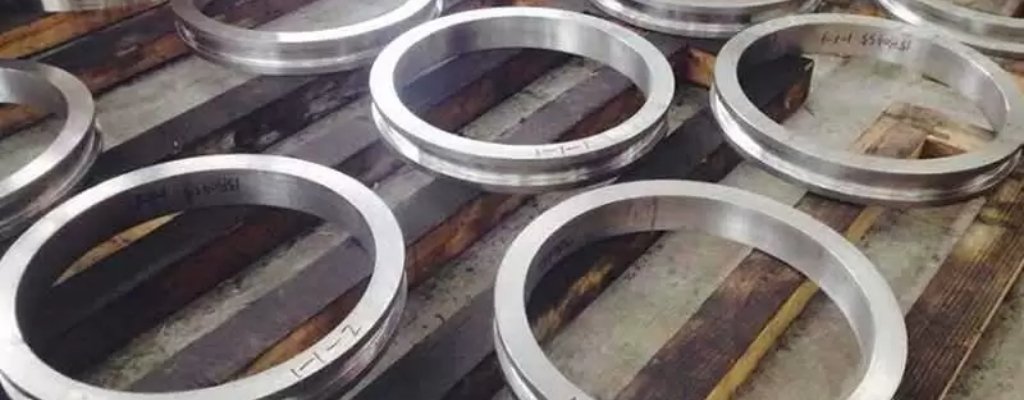

Manufacturing Equipment: Stainless Steel 304 Circle Rings are employed in the manufacturing sector for fabricating machinery components such as gears, bearings, and rollers, where their robustness and resistance to corrosion ensure longevity and reliability.

Machinery Construction: These rings are utilized in the construction of machinery for various industries, including automotive, textile, and food processing, where they provide structural support, stability, and resistance to wear and tear.

Architectural Applications: Stainless Steel 304 Circle Rings are incorporated into architectural designs for decorative purposes such as ornamental railing components, sculpture frames, and interior design elements due to their aesthetic appeal and corrosion resistance.

Pipeline Systems: In industries such as oil and gas, water treatment, and chemical processing, these rings are used in pipeline systems for sealing connections, supporting piping, and facilitating fluid flow, ensuring leak-proof and reliable operation.

Industrial Valves and Fittings: Stainless Steel 304 Circle Rings are employed in the fabrication of industrial valves and fittings for their resistance to corrosion and erosion, ensuring the integrity and performance of fluid control systems.

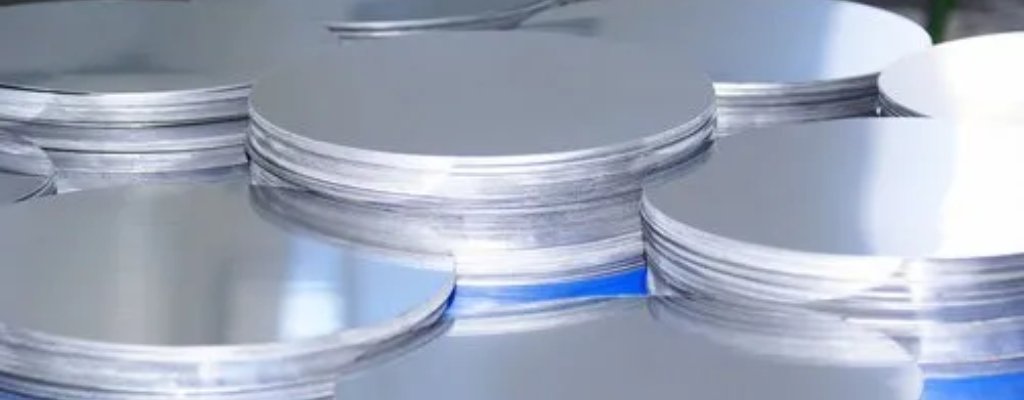

Food Processing Equipment: These rings are utilized in food processing equipment such as mixers, conveyors, and storage tanks due to their hygienic properties, corrosion resistance, and compliance with food safety standards.

Automotive Components: Stainless Steel 304 Circle Rings find applications in automotive components such as exhaust systems, engine parts, and chassis components for their durability, corrosion resistance, and ability to withstand harsh operating conditions.

Medical Instruments: In the medical industry, these rings are used in the fabrication of surgical instruments and medical devices for their biocompatibility, corrosion resistance, and ease of sterilization.

Electrical Enclosures: Stainless Steel 304 Circle Rings are employed in the construction of electrical enclosures and cabinets for their durability, corrosion resistance, and ability to protect sensitive electrical components from environmental factors.

Agricultural Machinery: These rings find applications in agricultural machinery such as tractors, plows, and harvesters for their resistance to corrosion and abrasion, ensuring reliable performance in agricultural operations.