| Equal Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Unequal Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Male Branch Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Female Branch Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

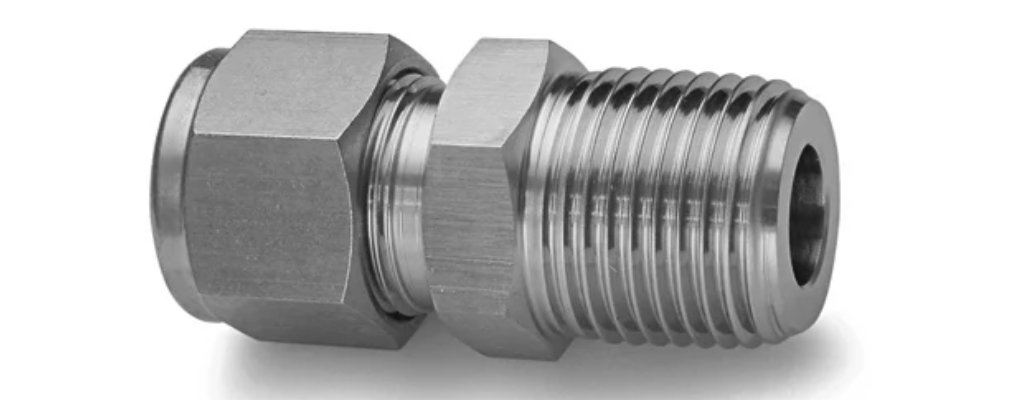

| Male (Hex Body) |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Female (Hex Body) |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Female Tee (Round Body Threaded) |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Female Tee (Round Body Socket Weld) |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Industrial Piping Systems |

| Street Tee (Hex Body) |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Street Tee (Round Body SW) |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Industrial Piping Systems |

| Branch Tee (Hex Body) |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Branch Tee (Round Body SW) |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Industrial Piping Systems |

| Union Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Reducing Union Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Male Run Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Positionable Male Run Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Positionable Branch Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Positionable Male Branch Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |

| Female Run Tee |

Stainless Steel, Brass, Carbon Steel, or other suitable material |

Various sizes available to match pipe dimensions |

Plumbing, Industrial Piping Systems |