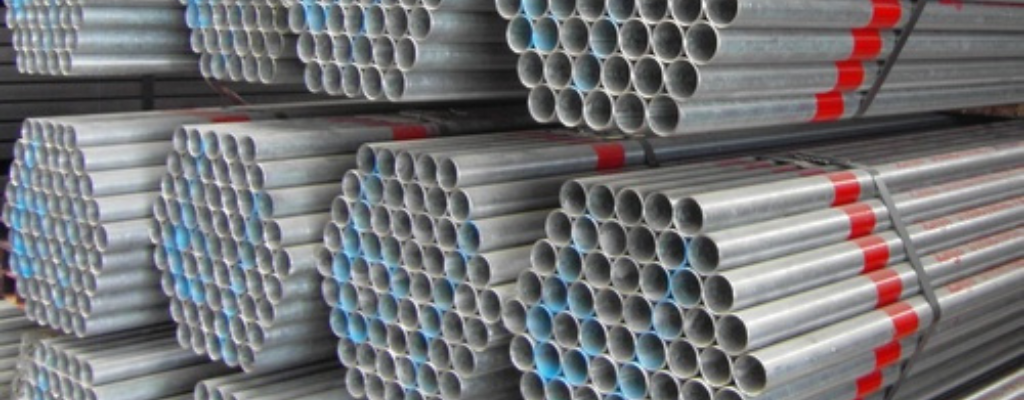

Mild steel pipes and tubes are essential components in various industrial and construction applications. Characterized by their durability, affordability, and versatility, these pipes and tubes are fabricated from low-carbon steel, offering excellent weldability and machinability. Mild steel pipes and tubes find widespread use in transporting fluids, gases, and solids in plumbing, irrigation, HVAC systems, and structural frameworks. Their adaptability to bending and shaping allows for easy installation in diverse environments. These components play a crucial role in infrastructure development, manufacturing processes, and everyday utilities, making them indispensable in modern engineering and construction projects.

Specifications for Mild Steel Pipes and Tubes

| Property | Specification |

|---|---|

| Material Grade | Mild Steel |

| Size Range | Customizable |

| Wall Thickness | Varies based on size and application |

| Length | Standard lengths or customizable |

| Surface Finish | Black, galvanized, or as per requirement |

| Ends | Plain ends or threaded |

| Manufacturing Method | Seamless or welded |

| Standards | ASTM, BS, DIN, JIS, IS, etc. |

| Applications | Plumbing, irrigation, HVAC, structural |

| Corrosion Resistance | Low |

Uses of Mild Steel Pipes and Tubes

1. Plumbing: Used extensively in plumbing systems for water supply and drainage in residential, commercial, and industrial buildings.2. Irrigation: Employed for transporting water in agricultural irrigation systems, providing efficient distribution to crops.

3. HVAC Systems: Integrated into heating, ventilation, and air conditioning systems for conveying air, steam, and other fluids.

4. Structural Frameworks: Utilized in the construction of structural frameworks for buildings, bridges, and infrastructure projects due to their strength and load-bearing capacity.

5. Transportation of Solids: Ideal for conveying solid materials such as grains, ores, and construction materials in conveyor systems.

6. Fencing and Railing: Used as posts, rails, and supports in fencing and railing systems for boundary demarcation and safety purposes.

7. Scaffolding: Incorporated into scaffolding structures for supporting workers and materials during construction and maintenance activities.

8. Industrial Processes: Applied in various industrial processes such as manufacturing, fabrication, and machinery assembly for conveying fluids and gases.

9. Utility Piping: Employed in utility piping systems for gas distribution, firefighting, and wastewater management.

10. Automotive Industry: Utilized in the manufacturing of vehicle frames, exhaust systems, and chassis components due to their strength and formability.