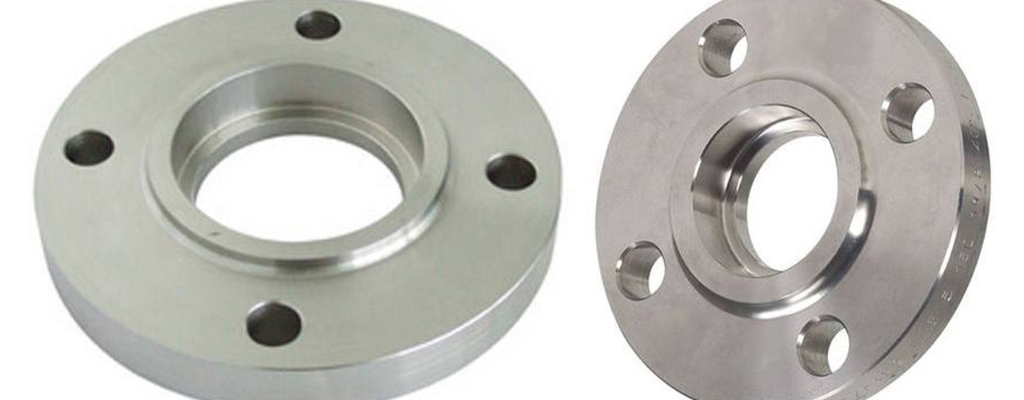

A slip-on flange is a type of flange that is slipped over the end of a pipe and then welded in place. It features a raised face with a bore that matches the pipe’s outer diameter, facilitating easy alignment and welding. Slip-on flanges are typically used in low-pressure applications where alignment of the bolt holes can be easily achieved. They are commonly employed in systems where frequent disassembly is not required and where the internal pressure and temperature are moderate. Slip-on flanges are favored for their ease of installation and cost-effectiveness, making them a popular choice in various industries, including petrochemical, chemical, and water treatment plants.

Specifications for Slip on Flange

| Property | Specification |

|---|---|

| Standard | ANSI B16.5, ASME B16.47, MSS SP-44, etc. |

| Material | Carbon steel, stainless steel, alloy steel, etc. |

| Size Range | 1/2″ to 48″ (15 NB to 1200 NB) |

| Pressure Rating | Class 150, Class 300, Class 600, etc. |

| Facing Type | Flat Face (FF), Raised Face (RF) |

| Connection Type | Slip-On |

| Flange Facing Finish | Smooth, serrated |

| Dimensions Standard | ASME B16.5, ASME B16.47 |

| Applications | Petrochemical, chemical, water treatment plants, etc. |

| Standards Compliance | ASTM A105, ASTM A182, ASTM A350, etc. |

Uses of Slip on Flange

1. Easy Installation: Slip-On Flanges are preferred in applications where ease of installation is essential. They can be easily slipped over the pipe and welded into place, reducing installation time and labor costs.

2. Low Pressure Applications: These flanges are commonly used in low-pressure applications where the internal pressure is relatively low. They provide a secure connection while minimizing stress on the flange joint.

3. Non-Critical Applications: Slip-On Flanges are suitable for non-critical applications where frequent disassembly is not required. They are commonly used in systems with moderate internal pressure and temperature.

4. Cost-Effective Solution: Slip-On Flanges are cost-effective compared to other types of flanges, making them a preferred choice for budget-conscious projects. Their simple design and ease of installation contribute to cost savings.

5. Alignment Flexibility: Slip-On Flanges offer flexibility in alignment during installation. The pipe can be easily aligned with the flange before welding, ensuring proper alignment of bolt holes and reducing the risk of misalignment.

6. Versatile Application: These flanges find application in various industries including petrochemical, chemical, water treatment plants, and general industrial applications. They are used in piping systems for connecting pipes, valves, and equipment.

7. Suitable for Smooth-Bore Piping: Slip-On Flanges are suitable for use in smooth-bore piping systems where turbulence and pressure drop are not critical factors. They provide a smooth transition between pipe sections, minimizing flow disruption.

8. Compatible with Raised Face and Flat Face Flanges: Slip-On Flanges are compatible with both raised face (RF) and flat face (FF) flanges, offering versatility in connecting different types of flanges within the same piping system.